-

Home

-

Products

-

Service

-

About Us

-

Solution

-

Videos

-

News

-

Contact Us

Leave Your Message

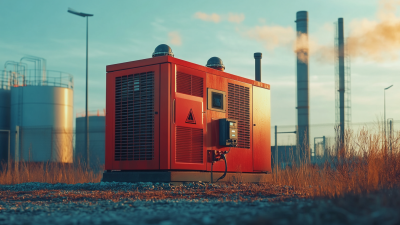

In today's industrial landscape, the need for reliable and efficient power solutions has never been more critical. Diesel generators large enough to meet high-demand applications are increasingly favored due to their robust performance and longevity. According to a report by MarketsandMarkets, the global diesel generator market is projected to reach USD 27.7 billion by 2026, driven by the growing demand for uninterrupted power supply in sectors such as manufacturing, construction, and oil and gas. These large diesel generators not only provide a crucial backup during power outages but also serve as a primary power source in off-grid locations. With advancements in technology, today's diesel generators are equipped with features such as remote monitoring and emissions control, making them a sustainable choice for industries striving to reduce their carbon footprint. Understanding the operational efficiencies, maintenance needs, and the latest innovations in large diesel generators is essential for organizations looking to unlock their full potential in industrial applications.

Large diesel generators play a crucial role in various industrial applications, particularly in data centers, which rely heavily on continuous power for their essential functions. Understanding the key components of these generators is vital to ensuring operational efficiency and reliability. The primary components include the engine, alternator, fuel system, control panels, and ventilation systems. Each part has a specific function, such as the engine converting diesel fuel into mechanical energy, while the alternator transforms this mechanical energy into electrical energy.

Moreover, the integration of Selective Catalytic Reduction (SCR) technology in diesel generators can enhance their environmental performance by reducing harmful emissions. For industries looking to optimize their power systems, understanding these components and their operation principles is fundamental. As energy demands increase, especially in sectors like data processing and storage, adopting reliable diesel generator systems equipped with advanced technologies will be essential to meet operational challenges and regulatory standards.

This chart illustrates the power output (in kW) of several large diesel generators commonly used in industrial settings. The data reflects typical values for generators ranging from 1000 kW to 3000 kW, highlighting their capabilities in meeting industrial energy demands.

As industries increasingly face unprecedented demand pressures, particularly highlighted by the North American Electric Reliability Corp.'s forecast predicting over a 50% rise in summer peak demand, the role of large diesel generators becomes critical in evaluating an organization’s energy requirements. When determining generator needs, businesses must assess their operational peak loads, which can vary significantly based on production schedules and equipment efficiency. With blackouts threatening over half of North America, resilient energy solutions like diesel generators are essential to maintaining continuity in industrial operations.

Moreover, understanding the intricacies of emergency power supply systems is vital. These systems comprise various components, including transfer switches and fuel storage that ensure an uninterrupted power supply. In light of the recent shifts within the power and utilities sector, organizations should conduct a thorough analysis of their energy usage patterns and potential growth trajectories. This proactive approach enables the selection of a generator capable of meeting current and future demands, effectively mitigating risks associated with power shortages and ensuring compliance with evolving energy regulations.

Investors should also consider the evolving landscape of energy storage technologies, which, while often undervalued, represent a significant opportunity for enhancing resilience. As industries evaluate their power needs, incorporating advanced energy solutions can augment traditional diesel generators, aligning with the comprehensive energy strategies outlined in integrated energy plans being adopted across various regions. This dual approach not only secures immediate power needs but also prepares organizations for a sustainable energy future.

| Generator Model | Power Output (kW) | Fuel Consumption (L/h) | Runtime (hrs) | Noise Level (dB) |

|---|---|---|---|---|

| Model A | 1000 | 200 | 8 | 75 |

| Model B | 1500 | 250 | 10 | 78 |

| Model C | 2000 | 300 | 12 | 80 |

| Model D | 2500 | 350 | 14 | 82 |

When it comes to maintaining large diesel generators for industrial use, consistent care plays a pivotal role in ensuring their longevity and reliability. Research indicates that proper maintenance can increase the lifespan of diesel generators by up to 40%, leading to significant cost savings in the long run. Key maintenance tasks should include regular oil changes, checking fuel filters, and keeping an eye on battery health. This not only minimizes downtime but also enhances the generator's performance during critical operations, especially in sectors where power reliability is essential.

When it comes to maintaining large diesel generators for industrial use, consistent care plays a pivotal role in ensuring their longevity and reliability. Research indicates that proper maintenance can increase the lifespan of diesel generators by up to 40%, leading to significant cost savings in the long run. Key maintenance tasks should include regular oil changes, checking fuel filters, and keeping an eye on battery health. This not only minimizes downtime but also enhances the generator's performance during critical operations, especially in sectors where power reliability is essential.

Moreover, considering the increasing demand for sustainable energy solutions, it's important to integrate best practices that align with current trends. For example, hybrid renewable energy systems, combining diesel generators with solar or wind power, can optimize efficiency while reducing emissions. Reports suggest that this hybrid approach can decrease operational costs by 20-30% and bolster energy resilience during climate-induced emergencies. Therefore, a comprehensive maintenance strategy that incorporates these innovative solutions will not only support the functionality of large diesel generators but also promote a greener industrial environment.

When selecting a large diesel generator for industrial use, several critical factors must be considered to ensure optimal performance and reliability. One essential aspect is the generator's power output, measured in kilowatts (kW), which should align with the specific energy demands of your operations. Conducting a thorough analysis of your facility's power requirements will help you avoid both under-sizing and over-sizing the generator, leading to cost savings and increased efficiency.

Another important consideration is the generator's fuel efficiency and operating costs. Diesel engines are known for their fuel efficiency, but variations exist among different models. It is essential to evaluate the fuel consumption rates and maintenance requirements of the generator to estimate long-term operational expenses accurately. Furthermore, consider the environmental regulations and noise levels, as compliance with local laws can impact the choice of model and installation location. By carefully weighing these factors, you can select the right diesel generator that meets your industrial needs while ensuring sustainability and cost-effectiveness.

Operating diesel generators in industrial settings necessitates rigorous adherence to safety protocols to mitigate risks and ensure optimal performance. One of the foremost best practices is to conduct a thorough risk assessment before commencing any operation. This includes evaluating the generator's location, ensuring it is installed away from flammable materials, and verifying that there is adequate ventilation to prevent the buildup of harmful exhaust gases. Establishing a designated area for generator use that is clearly marked can further enhance safety by restricting access to authorized personnel only.

Regular maintenance and inspection are also crucial for safe generator operation. Operators should be trained to identify signs of wear, leaks, or unusual noises that could indicate mechanical issues. Implementing a routine check-up schedule not only extends the lifespan of the equipment but also minimizes the likelihood of operational failures that could pose safety hazards. Additionally, providing staff with comprehensive safety training on emergency shutdown procedures, fire safety, and proper handling of fuel can significantly reduce the risk of accidents, ensuring a safe working environment while maximizing the functional benefits of large diesel generators.